Polytech Projects LLP is Manufacturer, Supplier and Exporter of Pickling Tank for Fasteners in Algeria.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

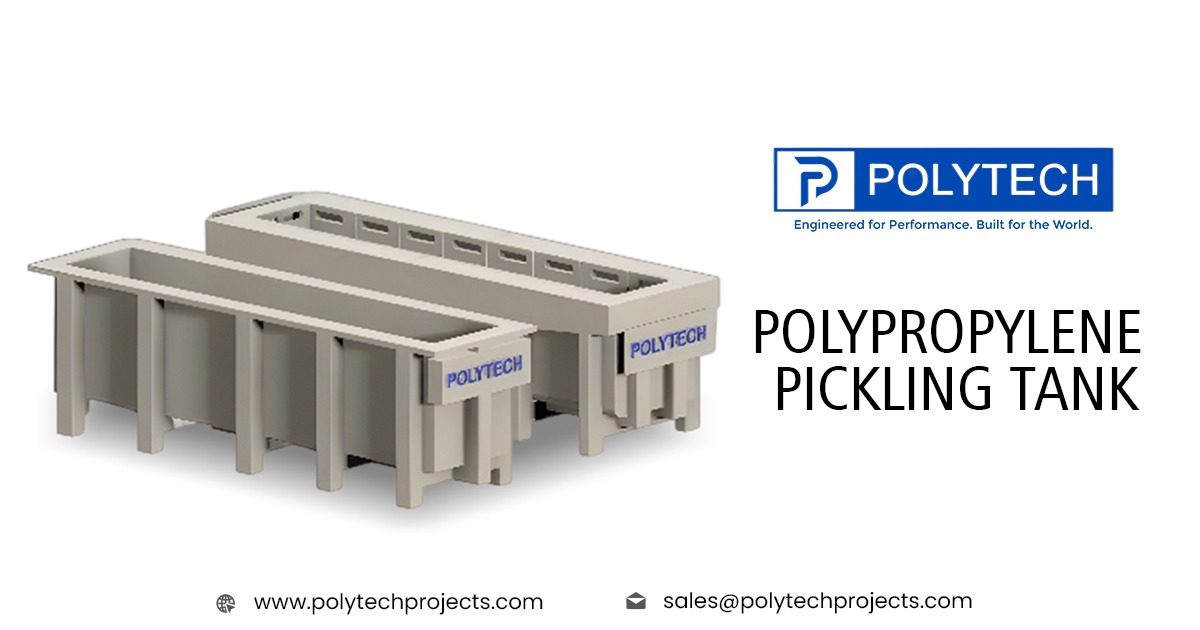

A Pickling Tank for Fasteners cleans, descales, and treats various metallic fasteners efficiently.

We specifically design it to process bolts, nuts, washers, screws, anchors, studs, and threaded metal components safely.

The pickling process effectively removes oil, grease, rust, scale, and welding residues from fastener surfaces before finishing.

This treatment ensures smooth, clean, corrosion-resistant, and paint-ready metal surfaces for enhanced durability and performance.

Polytech Projects LLP is a reputed manufacturer and supplier of advanced Pickling Tanks for industrial fastener applications.

We engineer our tanks for reliability, safety, and long-term performance in demanding surface treatment environments.

We construct them using superior PP, HDPE, and FRP materials to ensure corrosion resistance and leak-proof operation.

Pickling is a surface finishing process in which we dip fasteners in acid solutions to remove impurities and oxidation layers.

The process enhances surface bonding and ensures proper coating, galvanizing, plating, or painting.

Polytech Projects LLP provides custom-designed pickling tanks with fume extraction systems, heating arrangements, chemical-resistant lining, and automation options.

Our tanks are widely used across fastener manufacturing plants, forging units, heat treatment shops, and metal finishing units.

A Pickling Tank for Fasteners holds pickling chemicals and fasteners to perform surface treatment.

The tank prevents chemical leakage, corrosion, and structural degradation while offering efficient processing and long operational life.

Features:

100% Leak-Proof & Corrosion Resistant Design.

Heavy-Duty Construction for industrial applications.

High Chemical Resistance for long service life.

Seamless, Stress-Free Welding & Structure.

Available in PP, FRP-Lined, and HDPE Variants.

Strong Reinforcement to Prevent Deformation.

Compatible with Heating Coils & Circulation Systems.

Designed for Continuous Pickling Cycles.

Applications:

Our Pickling Tanks are widely used in:

Fastener Manufacturing Units

Bolt & Nut Production Plants

Automobile Parts Cleaning Units

Steel Fabrication & Surface Treatment Units

Metal Finishing & Electroplating Facilities

Galvanizing and Heat Treatment Plants

FAQs:

Q1. Which acids are commonly used in pickling?

We most commonly use Hydrochloric Acid (HCl) and Sulfuric Acid (H₂SO₄) depending on the material and application.

Q2. Are your tanks resistant to corrosion and heat?

We make our tanks from PP, FRP, and HDPE to provide excellent chemical and temperature resistance.

Q3. Can these tanks be customized?

Yes, we provide complete customization in size, shape, thickness, and accessories.

Q4. Do you provide fume extraction systems?

Yes, fume hood covers and scrubber systems can be integrated.

Polytech Projects LLP is Manufacturer, Supplier and Exporter of Pickling Tank for Fasteners in Algeria Including Algiers, Constantine, Batna, Sétif, Djelfa, Annaba, Sidi Aïssa, Sidi Bel Abbès, Biskra, Tébessa, Ouargla, El Khroub, Tiaret, Bejaïa, Tlemcen, Bir el Djir, Bordj Bou Arreridj, Béchar, Blida, Skikda, Souk Ahras, Chlef, El Eulma, Bordj el Kiffan, Mostaganem, Touggourt, Médéa, Tizi Ouzou, El Oued, Laghouat, M’Sila, Jijel, Relizane, Saïda, Baraki, Guelma, Ghardaïa, Aïn Beïda, Maghnia, Bou Saâda, Bou Saada, Mascara, Khenchela, Barika, Messaad, Aflou, Aïn Oussera, Oran, Es Senia, Bab Ezzouar, Tamanrasset, Arzew, Aïn M’Lila, El Bayadh, Mohammadia, Khemis Miliana, Hamma Bouziane, Dar el Beïda.

Contact Details:

Call Us: +91 9408908275

Email Us: sales@polytechprojects.com

For further inquiries or customized solutions, feel free to contact us.

View Product: Click Here