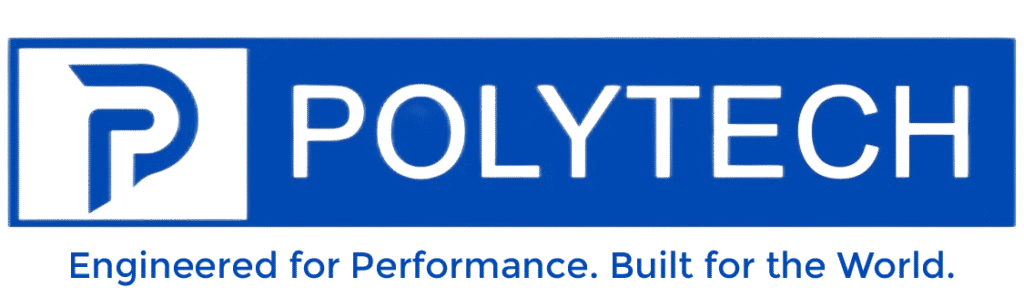

Polytech Projects LLP is Manufacturer, Supplier and Exporter of Hot Dip Galvanizing Pretreatment Plant in Algeria.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

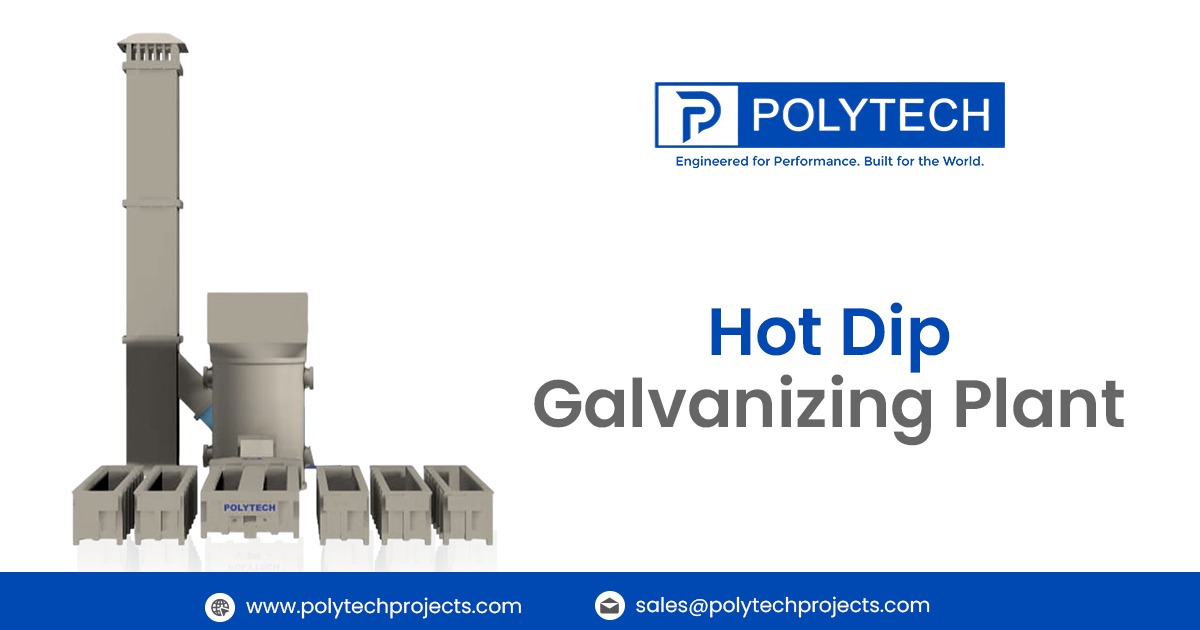

The Hot Dip Galvanizing Pretreatment Plant by Polytech Projects LLP is engineered to deliver superior surface preparation for steel products prior to galvanizing.

This plant ensures optimum cleaning, degreasing, pickling, rinsing, and fluxing, enabling strong and corrosion-resistant zinc coating.

Polytech Projects LLP specializes in manufacturing modern, reliable, and performance-driven pretreatment plants that meet global quality standards while ensuring safety, consistency, and environmental responsibility.

What is a Hot Dip Galvanizing Pretreatment Plant?

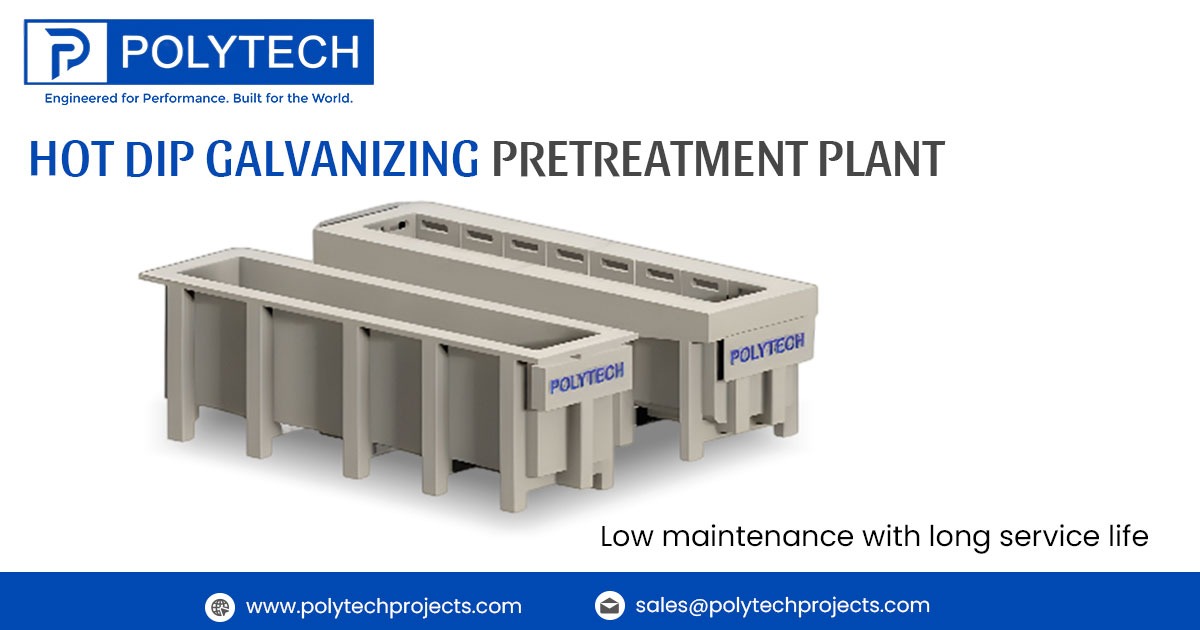

A Hot Dip Galvanizing Pretreatment Plant is an essential part of the galvanizing process, designed to prepare steel surfaces by removing oil, rust, scale, and contaminants before immersing the material in molten zinc. Pretreatment improves coating adhesion, ensures uniform zinc deposition, and significantly enhances corrosion resistance.

The plant typically includes tanks and systems for:

• Degreasing

• Pickling (acid cleaning)

• Rinsing

• Fluxing

• Drying

Proper pretreatment directly influences the quality, durability, and longevity of the final galvanized product.

Features:

Robust, acid-resistant construction designed for long-term durability.

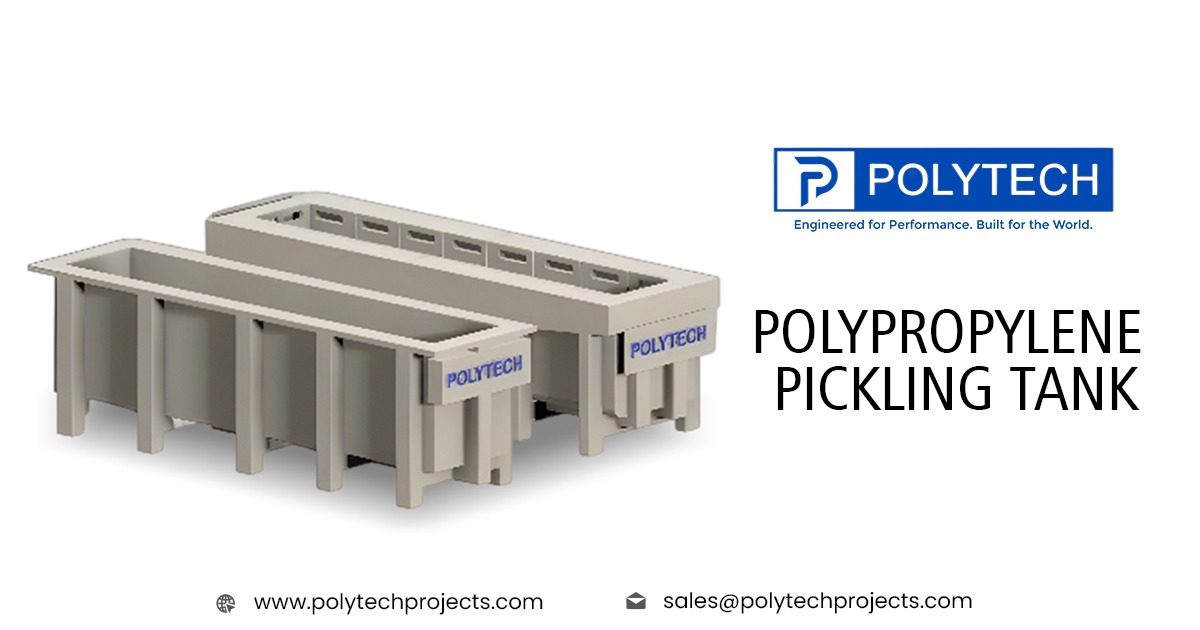

High-quality MS, PP, or FRP tanks tailored to process requirements.

Efficient degreasing, pickling, rinsing, and fluxing systems.

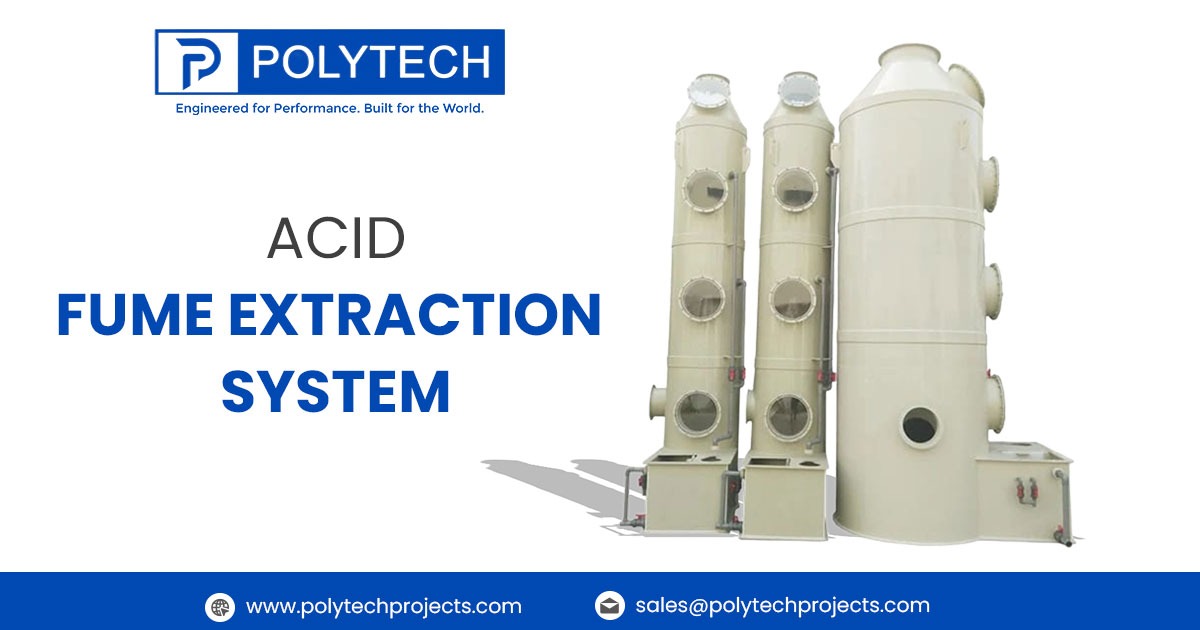

Comprehensive fume extraction and ventilation systems.

Automatic and manual handling options available.

Uniform heating solutions for consistent performance.

Advanced temperature and chemical concentration control.

Customizable plant size based on production capacity.

Environmentally safe and energy-efficient design.

Applications:

Our pretreatment solutions are ideal for:

Structural steel industries

Fabrication & engineering workshops

Transmission towers & poles

Agricultural tools

Automotive parts

Guard rails & highway structures

Racks, angles, channels, gratings

Machinery components

Fencing materials & wire products

Pipe & tubing manufacturers

FAQs:

Q1. What is the purpose of pretreatment in hot dip galvanizing?

Pretreatment removes contaminants, rust, and oxides to ensure strong zinc adhesion and uniform coating.

Q2. Which chemicals are used in the pretreatment process?

Common chemicals include alkaline cleaners, HCl or H2SO4 for pickling, and zinc-ammonium chloride for fluxing.

Q3. Can I customize tank sizes according to my material?

Yes! Polytech Projects LLP specializes in custom-designed pretreatment tanks based on your production needs and workflow.

Polytech Projects LLP is Manufacturer, Supplier and Exporter of Hot Dip Galvanizing Pretreatment Plant in Algeria Including Algiers, Constantine, Batna, Sétif, Djelfa, Annaba, Sidi Aïssa, Sidi Bel Abbès, Biskra, Tébessa, Ouargla, El Khroub, Tiaret, Bejaïa, Tlemcen, Bir el Djir, Bordj Bou Arreridj, Béchar, Blida, Skikda, Souk Ahras, Chlef, El Eulma, Bordj el Kiffan, Mostaganem, Touggourt, Médéa, Tizi Ouzou, El Oued, Laghouat, M’Sila, Jijel, Relizane, Saïda, Baraki, Guelma, Ghardaïa, Aïn Beïda, Maghnia, Bou Saâda, Bou Saada, Mascara, Khenchela, Barika, Messaad, Aflou, Aïn Oussera, Oran, Es Senia, Bab Ezzouar, Tamanrasset, Arzew, Aïn M’Lila, El Bayadh, Mohammadia, Khemis Miliana, Hamma Bouziane, Dar el Beïda.

Contact Details:

Call Us: +91 9408908275

Email Us: sales@polytechprojects.com

For further inquiries or customized solutions, feel free to contact us.

View Product: Click Here