Polytech Projects LLP is a Manufacturer, Supplier and Exporter of Surface Treatment Tank in Australia.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

Industries use Surface Treatment Tanks to perform chemical or electrochemical processes that effectively alter metal surface properties.

Industries employ these tanks to clean, plate, coat, anodize, etch, or passivate surfaces, enhancing corrosion resistance, adhesion, and aesthetics.

The tanks provide controlled environments for treatment solutions, ensuring uniform and high-quality surface modification in various applications.

Polytech Projects LLP designs and manufactures surface treatment tanks focusing on durability, chemical resistance, and operational efficiency.

We fabricate our tanks with high-grade materials that safely withstand aggressive chemicals used in surface treatment processes.

With advanced design features, the tanks ensure safe handling, minimal maintenance, and optimal treatment results across diverse industries.

Features:

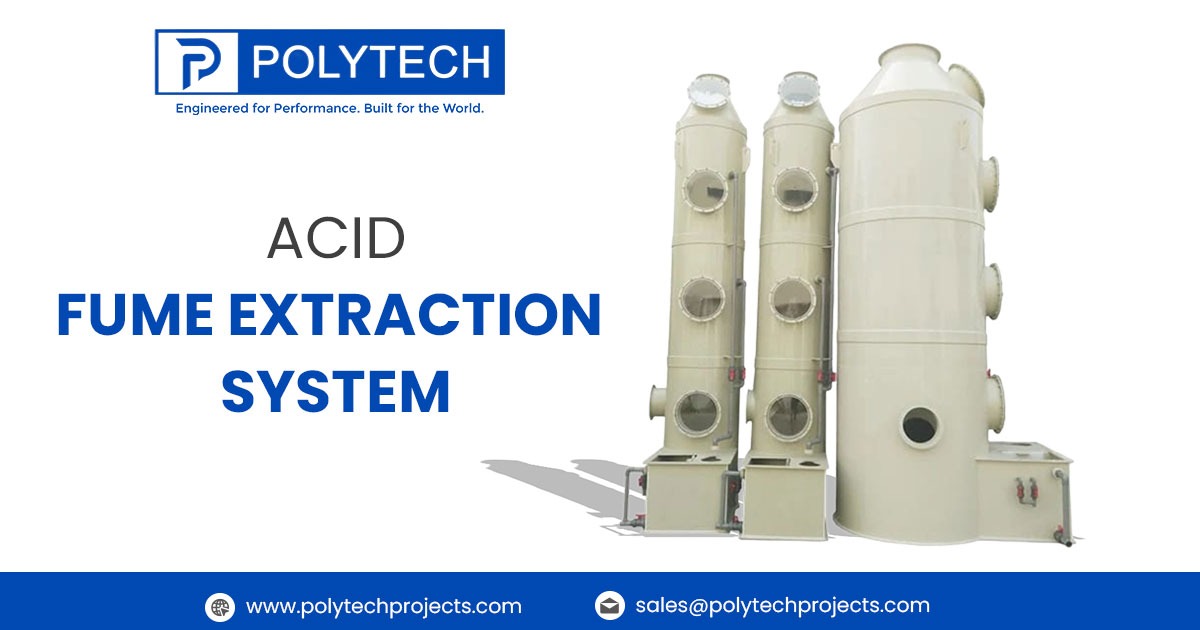

Corrosion-Resistant Materials: Tanks constructed from corrosion-resistant alloys or polymers to withstand aggressive chemical environments.

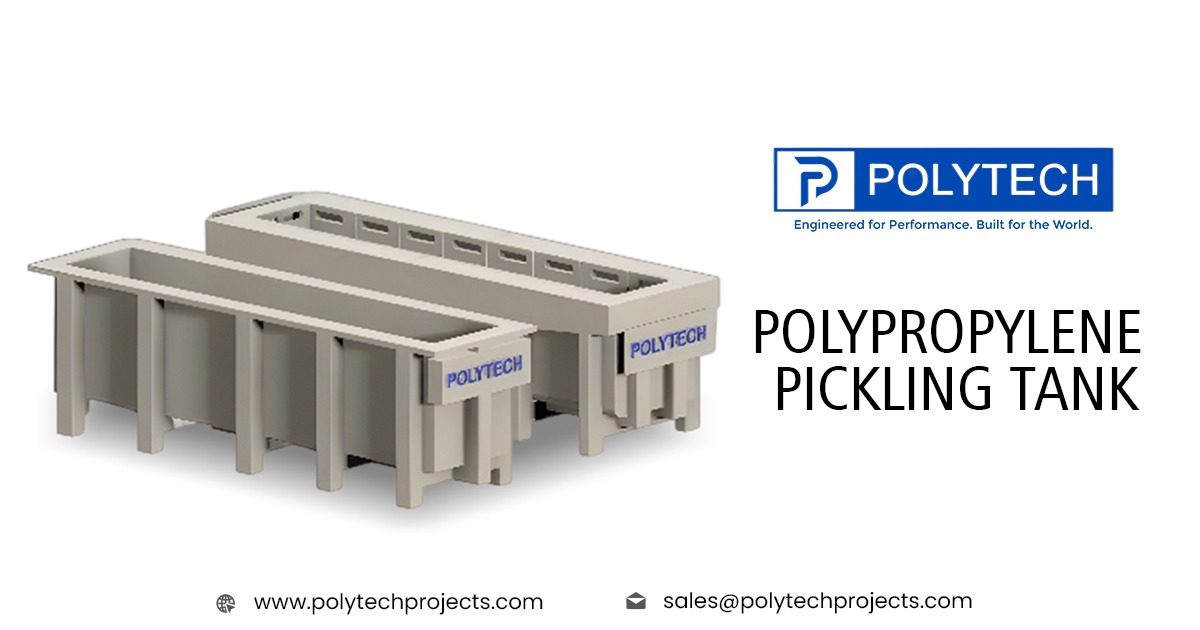

Versatile Configurations: Available in various shapes and sizes including rectangular, cylindrical, and custom designs.

Integrated Heating and Cooling: Optional systems to maintain optimal process temperatures.

Agitation Systems: Equipped with mechanical or pneumatic stirrers for uniform chemical action.

Easy Access: Designed with manholes, ladders, and drainage systems for convenience and safety.

Automation Ready: Can be integrated with automated process control for precise operation.

Durability: High resistance to abrasion and chemical attack ensures long service life.

Applications:

Automotive Industry: For metal finishing, rust removal, and coating of auto parts.

Electronics Manufacturing: Surface cleaning and plating of electronic components.

Aerospace: High-precision anodizing and passivation for aircraft components.

Metal Fabrication: Surface preparation and finishing of steel and aluminum products.

Chemical Industry: Corrosion resistance enhancement of equipment and pipelines.

Construction: Treatment of metal fittings and structural elements.

Frequently Asked Questions (FAQs):

Q1: What materials are used for manufacturing surface treatment tanks?

A1: We use stainless steel (SS304, SS316), polypropylene (PP), and fiber-reinforced plastic (FRP), selected based on chemical compatibility and process requirements.

Q2: Can the tanks be customized for specific applications?

A2: Yes, Polytech Projects LLP offers fully customizable tanks in terms of size, shape, and additional features like heating, agitation, and automation.

Projects LLP is a Surface Treatment Tank in Australia, Including Sydney, Albury, Armidale, Bathurst, Blue Mountains, Broken Hill, Campbelltown, Cessnock, Dubbo, Gosford, Goulburn, Grafton, Lithgow, Lismore, Liverpool, Newcastle, Orange, Parramatta, Penrith, Queanbeyan, Tamworth, Wagga Wagga, Wollongong.

For further details and inquiries, please feel free to contact us.