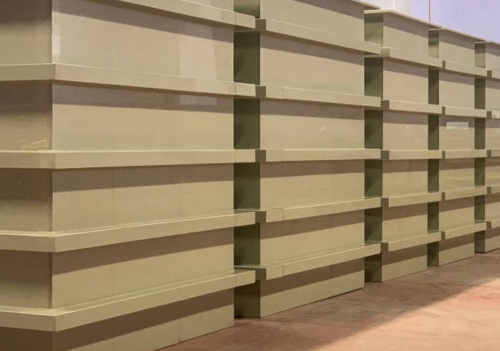

Process Tank line

Home » Our Product » Line » Process Tank Line

leading manufacturer of

Process Tank line

Polytech as long been a pioneer and innovator in the design, fabrication and installation of process tank lines

We Innovate, You Profit Polytech has long been a pioneer and innovator in the design, fabrication and installation of process tank lines. Whether you need a turnkey, multi hoist, completely automated computer-controlled process; a hand line; or individual process tanks or components, we will exceed your requirements.

20 + Years of

working experience

India's Most Trustworthy Brand Name in Mfg. Premium Range in Process Tank line.

- disciplines and capabilities

- No restrictions

- experience with equipment

- Licensed, general contractor

- In-house engineering & project management

- In-house steel and stainless-steel fabrication

- ASME Code approved welding shop

- In-house sandblasting, painting, coating and linings

- In-house plastic fabrication: Polypropylene, polyethylene, PVC, CPVC and PVDF

- In-house software development

- In-house mechanical and electrical assembly

- Field construction (concrete, mechanical and electrical)

- Field installation using our own personnel

- Outsourcing Panel Shop

- Space Availability

- Type of Material Handling

- Type of Work Handling: Rack, Basket or Barrel

- Tank Sizing & Construction

- Spill Containment Requirements

- Data Acquisition & Logging

- Loading & Unloading Requirements

- Ventilation Requirements

- Rinsing Requirements

- Drying Requirements

- Rectification

- Heating/Cooling

- Pumping Filtration

- Agitation

- Instrumentation

- Etching

- Anodizing

- Chem Film & Conversion Coatings

- Black Oxide

- Cleaning & Surface Prep

- Phosphate Coatings

- Electrolytic Plating

- Electroless Plating

- Passivation

- Electropolishing

- Stripping & many more

- Manufacturing Process

- Features

- Applications

- Understand the specific requirements and capacity needs of the client.Ensure the design adheres to local and international regulations and standards for safety and environmental considerations.

- Fabricate the large tank or kettle that will hold the molten zinc. This kettle is typically made of special materials to withstand high temperatures.

- Select materials for various components that can withstand the corrosive nature of the galvanizing process and provide a long service life.

- Prepare the site for the installation of the plant, including foundations and utilities.

- Conduct tests and inspections to ensure that each component meets quality standards.

- Implement safety measures for workers, including protective gear and protocols for working in high-temperature environments.

- Conduct comprehensive checks on all systems and equipment to ensure they function correctly.

- Provide the client with comprehensive documentation, including manuals, maintenance procedures, and safety guidelines.

- Galvanizing Kettle

- Flux Tank

- Drying Oven

- Quench Tank

- Handling Equipment

- Control Systems

- Construction Industry

- Transportation

- Utilities

- Infrastructure

- Agriculture

Our Products

Inquire here

Our Products

Inquire here

Process tank lines are a considerable business investment. We work closely with our customers and their chemical suppliers to engineer a system that provides lasting value and maximum ROI. We use proven, off-the-shelf standard components such as pumps, filters, rectifiers, motors, heaters, and electrical and automation equipment wherever possible. Most tank lines are constructed in modules for easy shipping and installation anywhere in the world.

Finally, we believe that the quality of our people sets us apart from our competition. We have over a dozen engineers staffing our engineering and project management group. Combined with PPL management, we have over 20 years of experience with the chemistry and equipment used in the surface finishing industry.

Technical Specifications

- Load Capacity: Handles 50–200 kg batch loads for small-to-medium scale educational processes.

- Extraction Rate: Achieves 10–20 L/hr fluid transfer using chemical-resistant pump and flow controls.

- Testing Equipment: Equipped with pH meter, conductivity meter, thermometer, and digital process timer.

- Drying Oven : Electric oven, 50–100L capacity, with PID controller for uniform post-process drying.

- Coating Thickness Control: Digital gauge measures 0–1000 microns for precise coating quality verification.

- FEATURES : Modular corrosion-resistant tanks, safety interlocks, fume hood, and user-friendly control panel.

- Applications : Used for electroplating, anodizing, etching, and surface preparation in engineering labs.