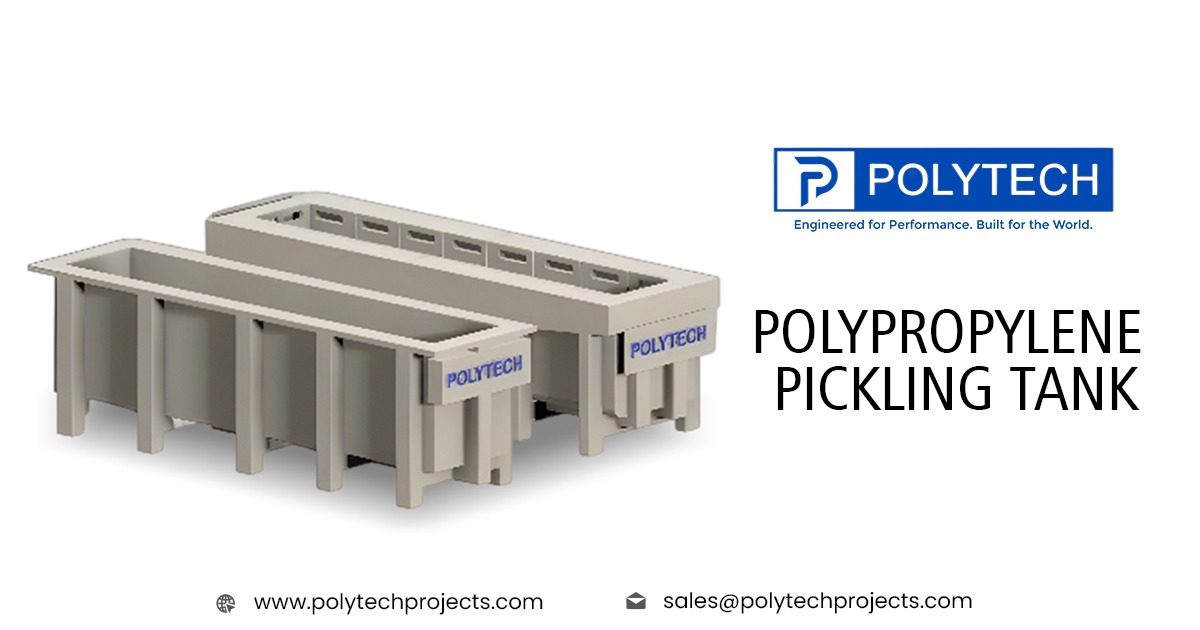

Polytech Projects LLP is a leading Manufacturer, Supplier, and Exporter of Thermoplastic Pickling Tank in Saudi Arabia.

Designed for industrial metal treatment processes, these tanks are ideal for cleaning, de-scaling, and surface preparation of metals such as stainless steel, mild steel, and alloy metals.

High-quality thermoplastic materials like PP (Polypropylene), PVDF, or HDPE construct the Thermoplastic Pickling Tank, providing superior chemical resistance, durability, and corrosion-free performance.

Engineers design these tanks to withstand aggressive acids used in pickling solutions, ensuring long service life with minimal maintenance.

Thermoplastic materials make a corrosion-resistant Thermoplastic Pickling Tank that holds acidic solutions for pickling and de-scaling metals.

Pickling is a process that removes rust, oxide layers, and impurities from metal surfaces, preparing them for further treatment like polishing, plating, or coating.

Features:

High corrosion resistance against acids and alkalis.

Lightweight and durable construction.

Smooth interior surface for easy cleaning and maintenance.

Resistant to chemical attack and surface degradation.

Can be customized for heating, agitation, or ventilation.

Available in different shapes and capacities.

Environmentally safe for acid storage and handling.

Modular design for easy installation and relocation.

Applications:

Polytech Projects LLP Thermoplastic Pickling Tanks are widely used in:

Metal Processing Industry: Pickling of stainless steel, mild steel, aluminum, and copper alloys.

Pharmaceutical Industry: Acid treatment for equipment cleaning.

Chemical Industry: Handling corrosive solutions for surface treatment.

Automobile Industry: Pre-treatment of metal components before painting or coating.

Food Processing Equipment Manufacturing: Cleaning and de-scaling stainless steel tanks and utensils.

Engineering Workshops: Rust and oxide removal from tools and machinery.

FAQs:

Q1: What is a pickling tank used for?

A1: It is used for cleaning and de-scaling metals by immersing them in acid solutions to remove rust, oxides, and impurities.

Q2: Why use thermoplastic tanks instead of metal tanks?

A2: Thermoplastic tanks are highly corrosion-resistant, lightweight, and safe for storing acidic solutions, unlike metal tanks which can corrode.

Q3: Can thermoplastic pickling tanks handle high temperatures?

A3: Yes, depending on the material (PP, PVDF, HDPE), they can handle temperatures up to 80–100°C.

Polytech Projects LLP is a Thermoplastic Pickling Tank in Saudi Arabia like Riyadh, Madinah, Makkah, Dammam, Jeddah, Taif, Tabuk, Buraydah, Hail, Hafar Al Batin, Al Jubail, Khamis Mushait, Al Bahah, Yanbu, Al Qatif, Abha, Jazan, Sakaka, Al Wajh, Arar, Al Qurayyat, Dhahran, Najran, Al Hofuf, Al Khobar, Duba, AlUla, Tanomah, Bisha, Khafji, As Sulayyil, Al Duwadimi, Az Zulfi, Ar Rass, Ad Dilam, Rabigh, Sabya, Safwa, Badr, Al Qaisumah, Turaif, Al Namas, Al Bukayriyah, Tubarjal, Al Artawiyah, Umm As Sahik, Al-Kharj, Farasan, Az Zaimah, Tarout.

Contact Details:

Call Us: +91 9408908275

Email Us: sales@polytechprojects.com

For detailed information or inquiries, please feel free to contact us.

View Product: Click Here