Polytech Projects LLP is Manufacturer, Supplier and Exporter of PP-H Process Tray in South Africa.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

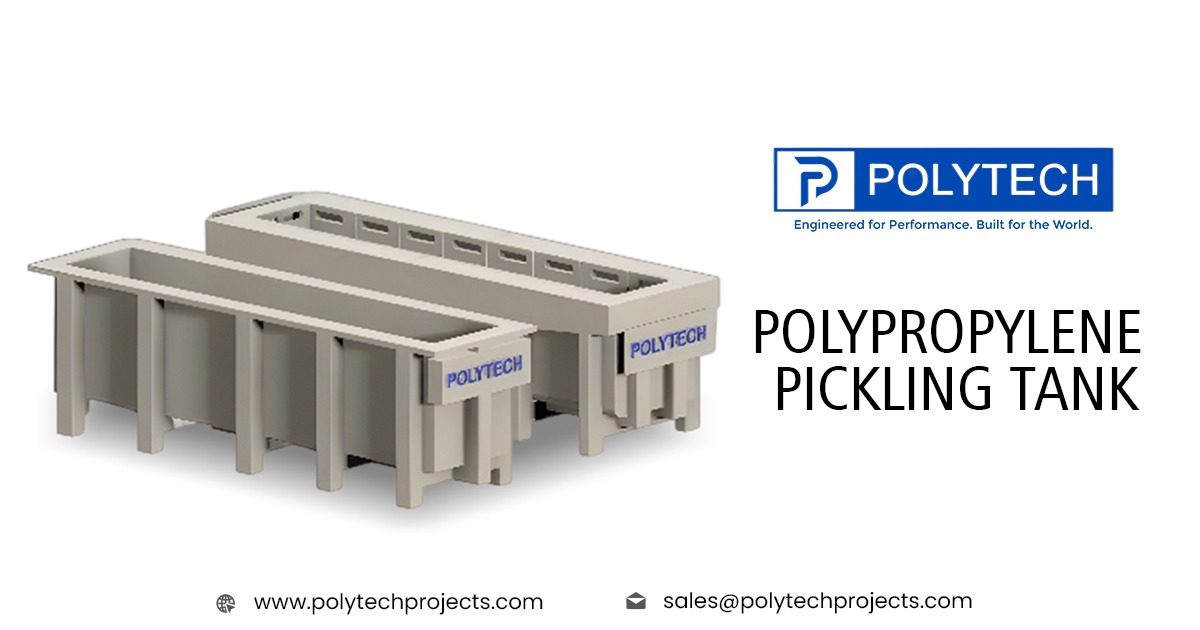

A PP-H Process Tray is a chemical-resistant tray used in process industries for the containment, handling, and transport of liquids and chemical solutions.

Made from homopolymer polypropylene, it ensures mechanical strength, thermal stability, and superior resistance to aggressive chemicals.

These trays are widely used in reactors, evaporators, scrubbers, and filtration systems as part of chemical process operations.

PP-H process trays are critical components in process columns, distillation towers, and scrubbers, contributing to efficient mass transfer, chemical reaction, or separation processes.

Features:

Constructed from high-purity PP-H material for maximum chemical resistance.

Lightweight yet durable, making installation and handling easy.

Customizable design to fit specific process columns or equipment.

High thermal and mechanical stability ensures reliable performance.

Smooth surface finish reduces corrosion and contamination.

Eco-friendly and non-toxic, suitable for chemical, pharmaceutical, and food industries.

Designed for low maintenance and long-term use.

Applications:

Chemical Industry: Distillation, absorption, scrubbing, and separation processes.

Pharmaceutical Industry: Processing of sensitive chemicals without contamination.

Water & Wastewater Treatment: Efficient separation of impurities and aeration processes.

Food & Beverage Industry: Corrosion-resistant trays for chemical mixing and filtration.

Industrial Processing: Mass transfer operations in reactors and towers.

FAQs on PP-H Process Tray

Q1: What is the difference between PP and PP-H material?

A: PP-H (Polypropylene Homopolymer) has higher rigidity, strength, and thermal stability compared to standard PP, making it ideal for industrial process trays exposed to harsh conditions.

Q2: Can PP-H Process Trays handle corrosive chemicals like acids and alkalis?

A: Yes, PP-H material is resistant to most acids, alkalis, and solvents, making it suitable for chemical processing and wastewater treatment applications.

Q3: Are PP-H Process Trays customizable?

A: Absolutely. Polytech Projects LLP designs trays in various shapes, thicknesses, and configurations to suit client-specific equipment and processes.

Polytech Projects LLP is a PP-H Process Tray in South Africa Including Johannesburg, Cape Town, Durban, Pretoria, Port Elizabeth, Bloemfontein, East London, Polokwane, Nelspruit, Kimberley, Rustenburg, Pietermaritzburg, Mbombela, George, Vereeniging, Witbank, Welkom, Upington, Grahamstown, Richards Bay, Mthatha, Uitenhage, Klerksdorp, and Potchefstroom.

Contact Details:

Call Us: +91 9408908275

Email Us: sales@polytechprojects.com

For further details and inquiries, please feel free to contact us.