Polytech Projects LLP is Manufacturer, Supplier and Exporter of Pickling Plant for SS Patta in South Africa.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

Polytech Projects LLP is a trusted name in industrial surface treatment and steel processing solutions.

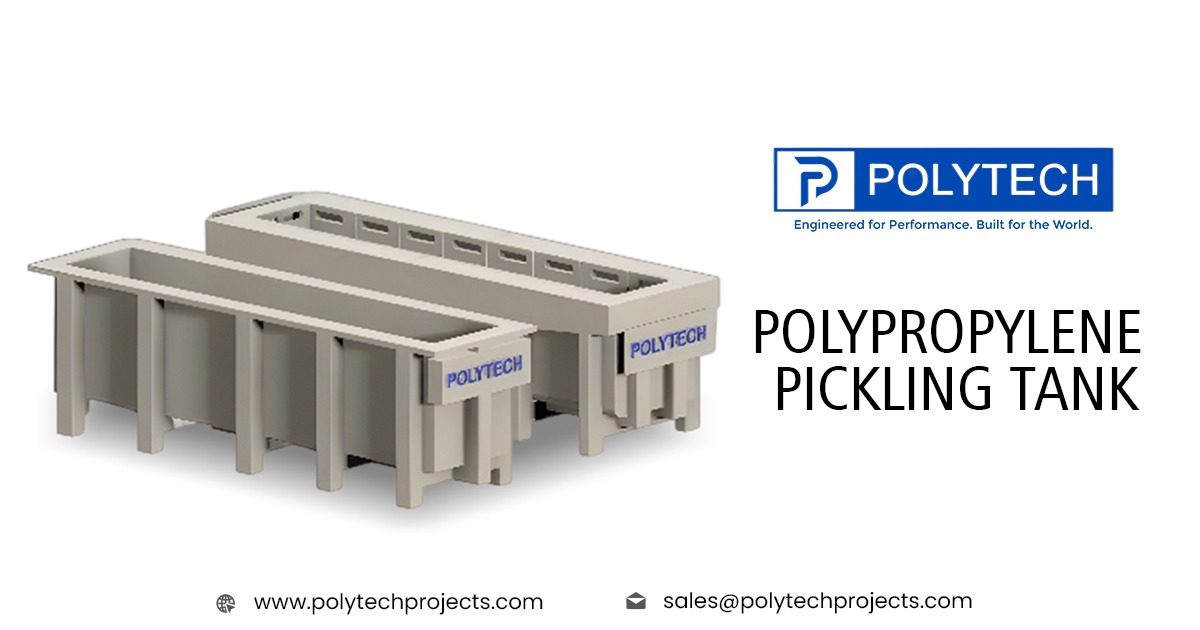

Our Pickling Plant for SS Patta is designed to deliver superior cleaning, descaling, and passivation of stainless steel strips (SS Patta) to improve corrosion resistance and surface finish.

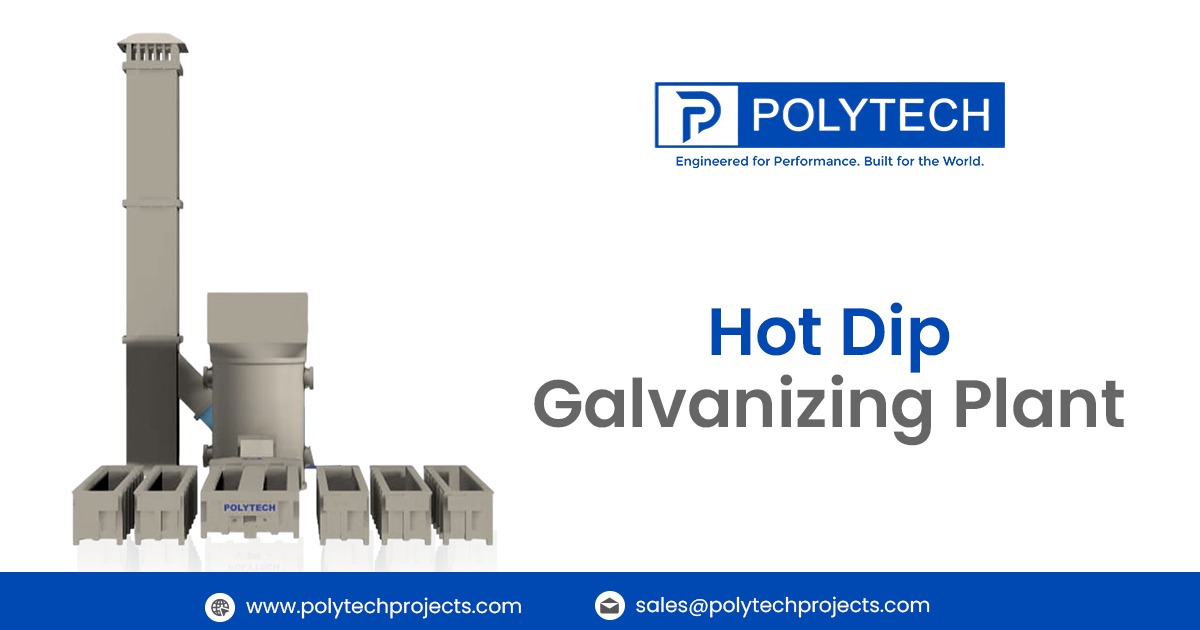

A Pickling Plant for SS Patta is an industrial setup designed to remove scales, oxides, and contaminants from stainless steel strips or pattas after rolling or heat treatment.

The process involves using a controlled acidic solution to clean the surface and restore the steel’s bright finish.

This step ensures better durability, corrosion resistance, and surface uniformity, making it a crucial part of stainless steel production.

Why Choose Polytech Projects LLP for Pickling Plants?

Expertise in Stainless Steel Surface Treatment – Years of experience in designing tailor-made pickling plants.

High Efficiency & Safety – Automated systems ensure safe handling of acids and minimize operator exposure.

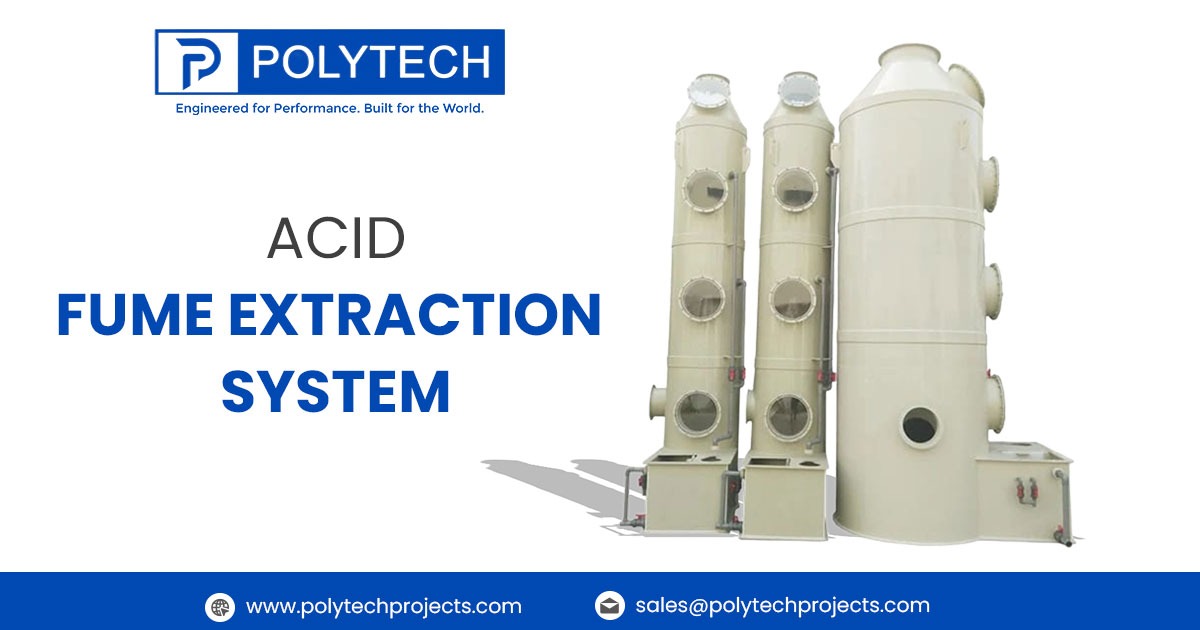

Eco-Friendly & Compliant – Designed with fume extraction, neutralization, and waste treatment systems.

Custom-Built Solutions – Plants built to your production capacity, SS grade, and process specifications.

Durable Construction – Corrosion-resistant tanks, piping, and structures.

Complete Support – From design to commissioning and after-sales service.

Features:

Heavy-duty acid-resistant tanks and piping.

Efficient fume extraction and scrubbing system to meet environmental norms.

Multiple stages of pickling, rinsing, and passivation.

Automatic acid circulation and filtration system.

Customizable layout to fit available space.

PLC-based control for accurate process monitoring.

Low maintenance design with durable materials.

Optional recovery system for acid and water to reduce costs.

Applications:

Our Pickling Plant for SS Patta is widely used in:

Stainless Steel Rolling Mills.

Steel Re-Rolling Plants.

Metal Fabrication Workshops.

Automotive Component Manufacturers.

Construction & Infrastructure Projects.

Kitchenware & Utensil Industries.

Chemical Processing Equipment Manufacturers.

Frequently Asked Questions (FAQs):

Q1: What is the main purpose of a pickling plant for SS Patta?

It removes scales, oxides, and impurities from stainless steel pattas, improving their surface finish and corrosion resistance.

Q2: Can Polytech Projects LLP customize the plant capacity?

Yes. We design pickling plants tailored to your production capacity, space, and process requirements.

Q3: How environmentally friendly is your pickling plant?

Our plants include advanced fume extraction, wet scrubbers, and neutralization systems to meet environmental regulations.

Polytech Projects LLP is a Pickling Plant for SS Patta in South Africa Including Johannesburg, Cape Town, Durban, Pretoria, Port Elizabeth, Bloemfontein, East London, Polokwane, Nelspruit, Kimberley, Rustenburg, Pietermaritzburg, Mbombela, George, Vereeniging, Witbank, Welkom, Upington, Grahamstown, Richards Bay, Mthatha, Uitenhage, Klerksdorp, and Potchefstroom.

Contact Details:

Call Us: +91 9408908275

Email Us: sales@polytechprojects.com

For further details and inquiries, please feel free to contact us.

View Product: Click Here