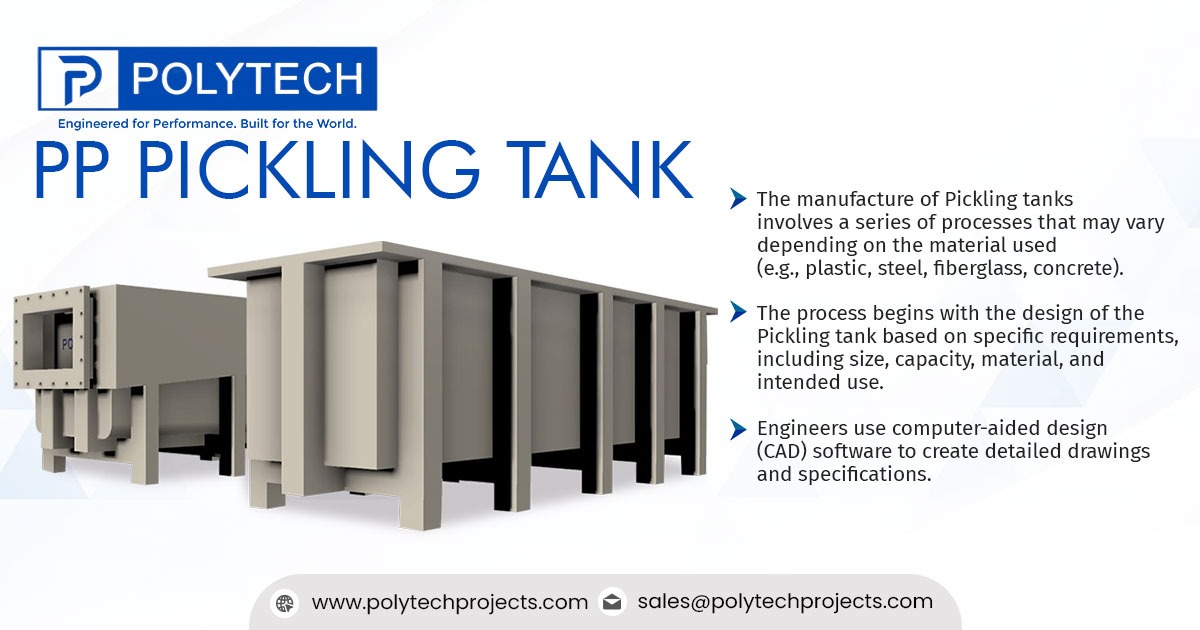

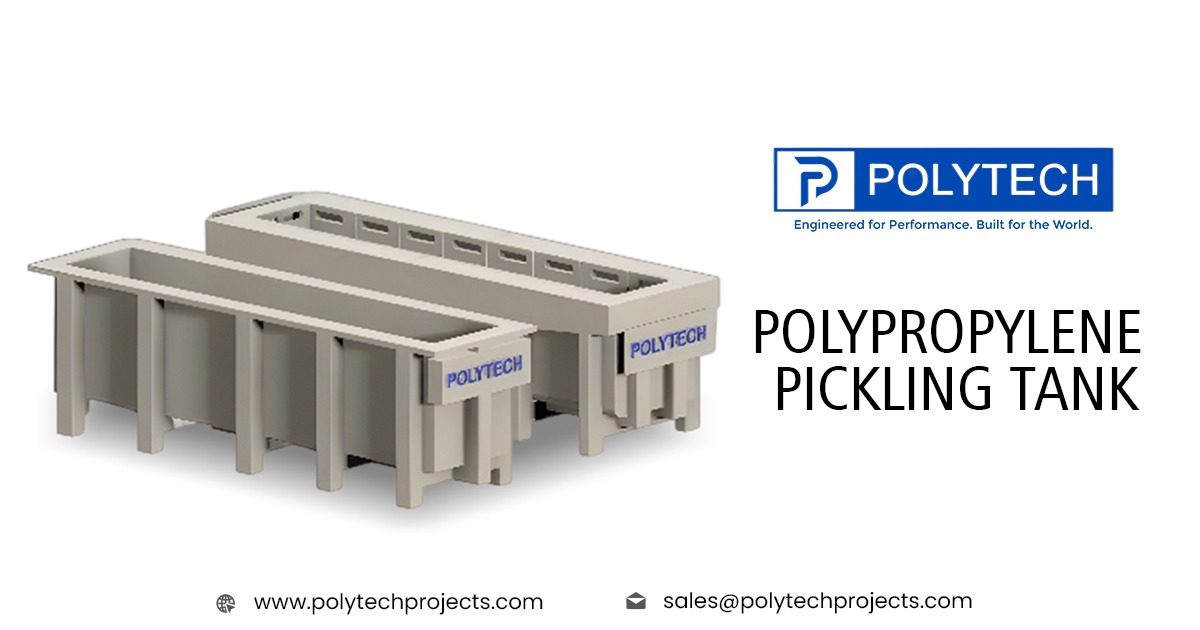

Polytech Projects LLP is Manufacturer, Supplier and Exporter of PP Pickling Tank in Australia.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

Polytech Projects LLP is a renowned name in delivering high-performance, corrosion-resistant PP Pickling Tanks for diverse industrial applications.

Made from premium-grade Polypropylene (PP), these tanks withstand aggressive chemicals in pickling, electroplating, galvanizing, and surface treatments.

As industries demand superior equipment for chemical processing, PP Pickling Tanks have emerged as an essential solution for safe, reliable, and efficient operations.

A PP Pickling Tank is a chemical-resistant storage or processing tank fabricated using Polypropylene (PP) sheets.

These tanks are primarily used for the pickling process, where metal components are treated with acid solutions to remove impurities, rust, and scale.

Polytech Projects LLP manufactures PP Pickling Tanks in various shapes, sizes, and configurations based on the specific industrial requirements.

Why Choose PP Pickling Tanks from Polytech Projects LLP?

Choosing Polytech Projects LLP means you’re investing in:

Superior Build Quality

Long-lasting Performance

Custom Designs

Chemical and Corrosion Resistance

Leak-proof Welding Technology

Compliance with Global Safety Standards

With decades of experience in plastic fabrication, Polytech Projects LLP ensures every tank is manufactured with precision, quality assurance, and complete customer satisfaction in mind.

Features:

High Chemical Resistance: Polypropylene resists strong acids (like HCl, H₂SO₄) and bases, ensuring long-term tank integrity.

Lightweight & Strong: PP offers a favorable strength-to-weight ratio—simpler handling and reduced infrastructure load.

Thermal Stability: Operates effectively in pickling temperature ranges up to ~80 °C without deformation.

Custom Fit: Fully customizable in size, capacity, mounting style, connections, and support structures.

Corrosion-Free: PP eliminates rust-related contamination, making it ideal for high purity operations.

Low Maintenance: Smooth surfaces minimize buildup, while PP is easy to clean and maintain.

Applications:

PP Pickling Tanks are widely used in:

Metal Pickling & Surface Treatment

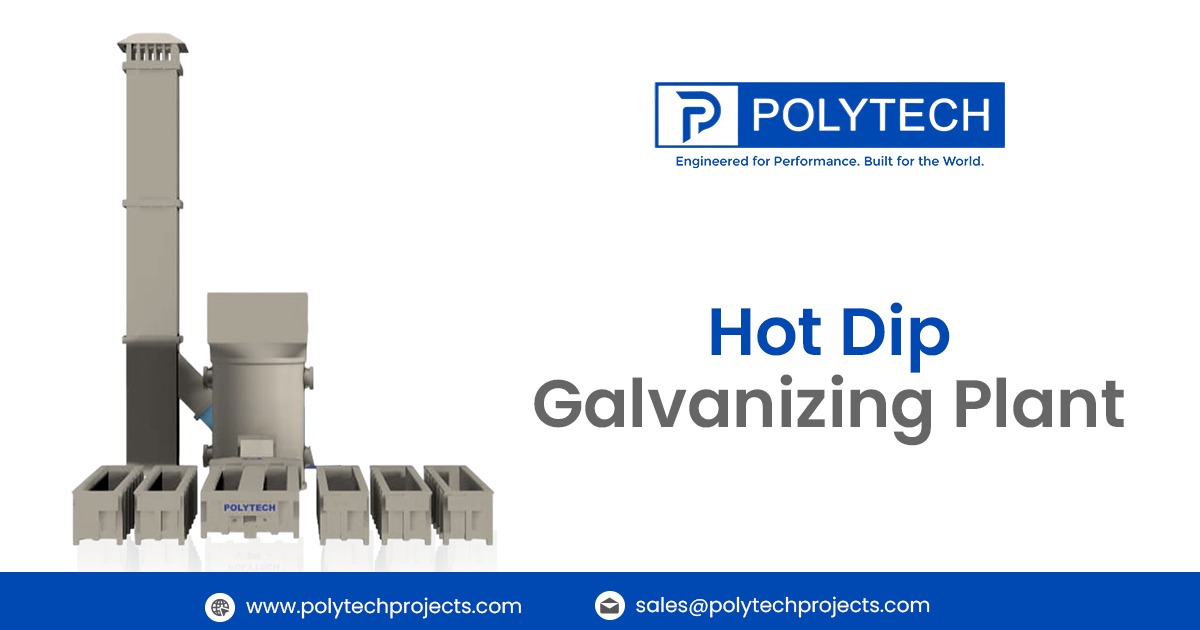

Galvanizing Plants

Electroplating & Anodizing

Automobile Component Cleaning

Degreasing Processes

Chemical Storage

Laboratory & R&D Units

Construction & Fabrication Workshops

These tanks are suitable for acidic and alkaline chemical processes, making them a versatile choice across multiple industries.

FAQs – PP Pickling Tank:

Q1. What is the lifespan of a PP Pickling Tank?

A: With proper usage and maintenance, a PP Pickling Tank can last 10+ years without corrosion or structural issues.

Q2. Can I use PP tanks for HCl and H₂SO₄ pickling?

A: Yes. Polypropylene is highly resistant to both hydrochloric acid and sulfuric acid, making it ideal for such applications.

Q3. Are your pickling tanks customizable?

A: Absolutely! We manufacture tanks as per client specifications – in terms of size, shape, reinforcement, and accessories.

Projects LLP is a PP Pickling Tank in Australia, Including Sydney, Albury, Armidale, Bathurst, Blue Mountains, Broken Hill, Campbelltown, Cessnock, Dubbo, Gosford, Goulburn, Grafton, Lithgow, Lismore, Liverpool, Newcastle, Orange, Parramatta, Penrith, Queanbeyan, Tamworth, Wagga Wagga, Wollongong.

Contact Details:

Call Us: +91 9408908275

Email Us: sales@polytechprojects.com

For further details and inquiries, please feel free to contact us.

View Product: Click Here