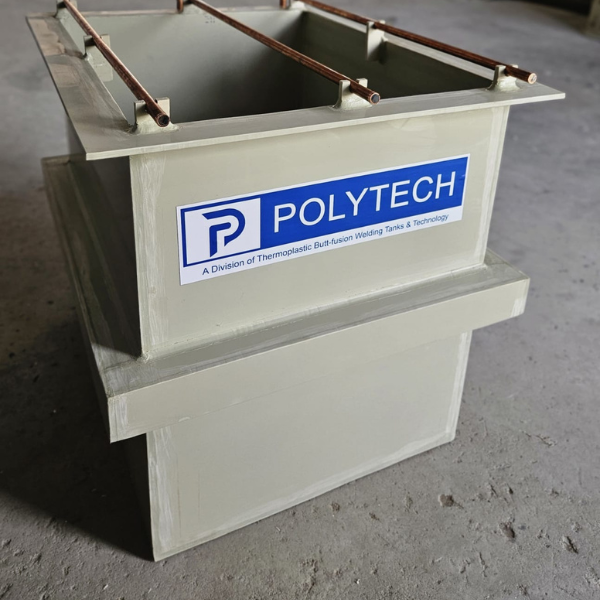

plating Tank

Home » Our Product » Tanks » Plating Tank

leading manufacturer of

plating tank

Plating tank have a square or rectangular cross-section, meaning all four sides are equal in length, and the corners form right angles. This shape differs from cylindrical or round tanks.

Plating tank, also known as rectangular tanks with equal sides, have a distinct geometric shape characterized by four right angles and equal-length sides. These tanks are utilized in various industries and applications for the storage of liquids, chemicals, and other materials.

20 + Years of

working experience

India's Most Trustworthy Brand Name in Mfg. Premium Range in plating tank.

- Manufacturing Process

- Features

- Applications

- The tank design is created, and molds are produced based on the design specifications. These molds determine the final shape and dimensions of the square tank

- The molded tank components are allowed to cool and set. The cooling process may involve controlled cooling chambers or natural air cooling.

- Inlet/outlet fittings, vents, and other accessories are installed as part of the assembly process.

- The completed tank is subjected to tests to ensure it is leak-proof and possesses the required structural strength.

- Tanks made of plastic may be manufactured in various colors. Coloring is often added during the material extrusion or molding stage.

- The finished plastic square tank is prepared for shipping and installation. The installation process involves placing the tank in its intended location and connecting it to the necessary plumbing or systems.

- Customizable Dimensions

- Easy Installation

- Stackability (for some materials)

- Top and Bottom Configurations

- Temperature Resistance

- Durability Across Materials

- Agriculture

- Water treatment

- Industrial processing

- Chemical storage

- Manufacturing Process

- Features

- Applications

- The tank design is created, and molds are produced based on the design specifications. These molds determine the final shape and dimensions of the square tank

- The molded tank components are allowed to cool and set. The cooling process may involve controlled cooling chambers or natural air cooling.

- Inlet/outlet fittings, vents, and other accessories are installed as part of the assembly process.

- The completed tank is subjected to tests to ensure it is leak-proof and possesses the required structural strength.

- Tanks made of plastic may be manufactured in various colors. Coloring is often added during the material extrusion or molding stage.

- The finished plastic square tank is prepared for shipping and installation. The installation process involves placing the tank in its intended location and connecting it to the necessary plumbing or systems.

- Customizable Dimensions

- Easy Installation

- Stackability (for some materials)

- Top and Bottom Configurations

- Temperature Resistance

- Durability Across Materials

- Agriculture

- Water treatment

- Industrial processing

- Chemical storage

Our Products

Inquire here

Our Products

Inquire here

Plating tank : The durability of plating tank depends on the material used in construction. Manufacturers select materials based on factors such as resistance to corrosion, chemical compatibility, and structural strength.

Plating tank can be constructed from a variety of materials, including but not limited to plastic (polyethylene), steel, stainless steel, fiberglass, and concrete. The material choice depends on factors such as the type of substance to be stored, durability requirements, and environmental conditions.

Technical Specifications

- Type : Tanks

- Material : plating tank can be made from various materials, including metals (such as steel or stainless steel), plastics (polyethylene), fiberglass, or a combination of materials. The choice of material depends on factors such as the type of substance to be stored, environmental conditions, and durability requirements.

- Thickness : 3mm to upto 50mm

- Moc : PP,HDPE,PVC,FRP,FRV

- Capacity: up to 1lac ltr

- Application : Water Storage , Industrial Processing , Chemical Storage , Industrial Manufacturing , Retail and Commercial Use

- Capacity : The capacity of the square tank is a crucial specification, indicating the maximum volume of liquid or material it can hold. It is typically measured in gallons, liters, or cubic meters.

- Feature : Modularity , Fittings and Accessories , Custom Colors (for some materials)