Services

Home » Services

Our services

We come along with you throughout the process and can assist you wherever you are stuck since

we are professionals in offering full-scale hot dip galvanizing plant solutions. We provide a variety of services to

guarantee faultless and seamless operations on your end. Our customer support team is here 24/7 to assist you

in overcoming obstacles with grace. Providing outstanding support to our customers is our main goal,

and we strive to achieve this through our wide range of support services.

Project Consultancy

Polytech Projects LLP provides turnkey solutions for best-of-breed hot dip galvanizing plants. Because of our experience and subject expertise, Polytech Project LLP specializes in all of these areas, from feasibility studies to engineering help to process design and commissioning support. Our goal as project consultants is to provide outstanding assistance by forming enduring relationships with our customers after carefully analyzing their needs. Our consulting program comprises providing the necessary guidance and assistance via the implementation of a tailored plan that may help your galvanizing facility expand more quickly. Having dealt with a variety of plant configurations, we offer the most appropriate and promising answer to.

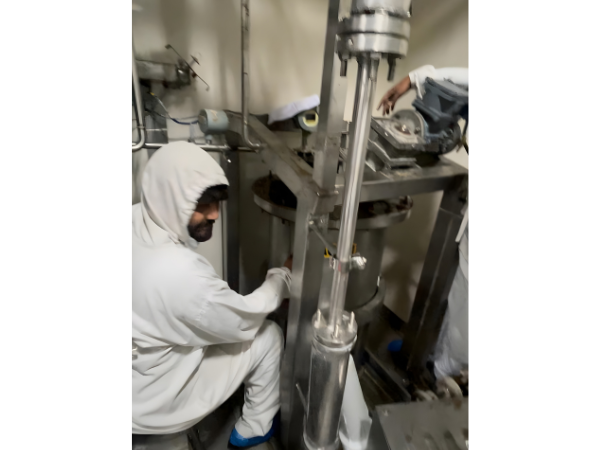

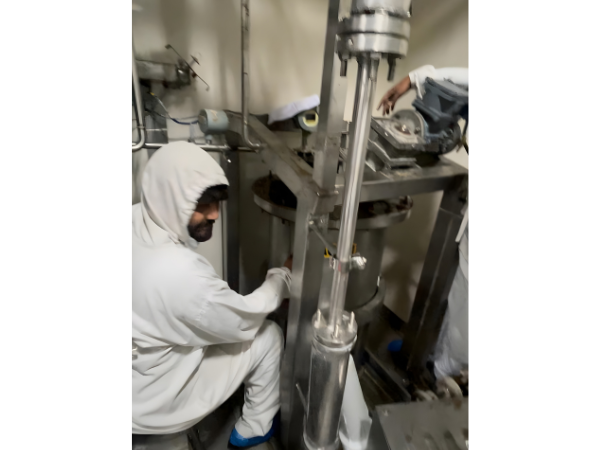

Process Tank Repairs

Process tanks for pre- and post-treatment are a noticeable feature of galvanising facilities. It is critical that these tanks be repaired quickly and effectively in order to ensure correct galvanising. Polytech Projects LLP provides risk-based assessments, spill prevention tests, and mechanical integrity evaluations for tanks. Our staff offers top-notch maintenance, repair, and modification services to ensure the long life of your tanks and has extensive experience solving issues with a wide range of tanks. We are able to offer thoughtful and accurate answers to the issues since we are familiar with every step of the hot dip galvanising process.

Annual Maintenance Contracts

Polytech Projects LLP, a leading producer of hot dip galvanizing plants, understands how important it is to routinely repair every piece of equipment to preserve performance and efficiency. We think that the secret to sustained plant performance is regular and scheduled preventative maintenance. Our group of knowledgeable engineers has the expertise and experience needed to handle your maintenance needs with elegance. By achieving the targeted outcomes as determined by the key performance metrics, we guarantee seamless and effective operations. You may save production loss by doing routine maintenance on schedule, which would also help to prevent unexpected equipment or machine breakdowns.

Spare Parts Supply

We produce every component needed for the hot dip galvanising process in accordance with international standards as a well-known Original Equipment Manufacturer of complete hot dip galvanising machines. We have provided complete solutions to numerous clients in several nations worldwide. In addition to providing turnkey plants and galvanising equipment, we also provide customization based on the client's requirements. With our extensive experience in providing solutions and products, we provide premium-grade replacement parts that are tailored to your specific needs. Every replacement component guarantees the greatest assistance and outstanding.

After Sales Service

Appropriate after-sale support is essential to your galvanising plant's functionality and security. Our clients are our first concern at Polytech Projects LLP. Not only do we state this, but every member of our team maintains this viewpoint. Not only do we assist you during the purchasing process, but we also remain available to assist you with any post-purchase needs. Our after-sale staff ensures that clients are happy with their purchases. If there is ever a performance issue, you can easily contact our professionals, who will take care of the problem.

Training and Development

Polytech Projects LLP is a provider of turnkey hot dip galvanising plants with the necessary competence, experience, and quality in the field. We provide a training and development service that involves educating your workers on the application and functioning of hot dip galvanising so you can get the most out of the plant asset. We would answer any questions your employees may have about their specific responsibilities, plant safety precautions, and optimal operating procedures. To guarantee "best practise," we educate your workers by walking them through each stage of the hot dip galvanising process.

Post Comissioning Support

success in terms of the impact of our equipment on the performance and long-term growth of our clients.

Zinc Kettle Replacement

The kettle holds utmost significance in the process of galvanising. Polytech Projects LLP offers premium zinc kettles with long-lasting galvanising that are efficient. With our Pulse-Fired High Velocity Furnaces, Kettle by Polytech Projects LLP can withstand high output levels for up to ten years. We customise zinc kettle for maximum efficiency based on your product and plant area. Our kettles are welded with electroslag and put through radiographic and ultrasonic testing. By using refractory casting fibre to insulate the bottom of the kettle and keep it from coming into direct touch with the burner's flames, we may prolong the kettle's lifespan.

Plant Upgrading

Polytech Projects LLP can quickly and effectively solve any operating problems or breakdowns because to its unparalleled experience. Using our knowledge and resources, we provide galvanising plant upgrading services and work with you to make this transition from antiquated systems to more sophisticated, modern ones. We examine your utilisation needs and end objectives to assist you in upgrading each and everything. Whether you are a cost-conscious person wishing to update a portion of the plant, a client seeking process optimisation, or a client prepared to update the plant.

Our services

We come along with you throughout the process and can assist you wherever you are stuck since

we are professionals in offering full-scale hot dip galvanizing plant solutions. We provide a variety of services to

guarantee faultless and seamless operations on your end. Our customer support team is here 24/7 to assist you

in overcoming obstacles with grace. Providing outstanding support to our customers is our main goal,

and we strive to achieve this through our wide range of support services.

Project Consultancy

Polytech Projects LLP provides turnkey solutions for best-of-breed hot dip galvanizing plants. Because of our experience and subject expertise, Polytech Project LLP specializes in all of these areas, from feasibility studies to engineering help to process design and commissioning support. Our goal as project consultants is to provide outstanding assistance by forming enduring relationships with our customers after carefully analyzing their needs. Our consulting program comprises providing the necessary guidance and assistance via the implementation of a tailored plan that may help your galvanizing facility expand more quickly. Having dealt with a variety of plant configurations, we offer the most appropriate and promising answer to.

Process Tank Repairs

Process tanks for pre- and post-treatment are a noticeable feature of galvanising facilities. It is critical that these tanks be repaired quickly and effectively in order to ensure correct galvanising. Polytech Projects LLP provides risk-based assessments, spill prevention tests, and mechanical integrity evaluations for tanks. Our staff offers top-notch maintenance, repair, and modification services to ensure the long life of your tanks and has extensive experience solving issues with a wide range of tanks. We are able to offer thoughtful and accurate answers to the issues since we are familiar with every step of the hot dip galvanising process.

Annual Maintenance Contracts

Polytech Projects LLP, a leading producer of hot dip galvanizing plants, understands how important it is to routinely repair every piece of equipment to preserve performance and efficiency. We think that the secret to sustained plant performance is regular and scheduled preventative maintenance. Our group of knowledgeable engineers has the expertise and experience needed to handle your maintenance needs with elegance. By achieving the targeted outcomes as determined by the key performance metrics, we guarantee seamless and effective operations. You may save production loss by doing routine maintenance on schedule, which would also help to prevent unexpected equipment or machine breakdowns.

Spare Parts Supply

We produce every component needed for the hot dip galvanising process in accordance with international standards as a well-known Original Equipment Manufacturer of complete hot dip galvanising machines. We have provided complete solutions to numerous clients in several nations worldwide. In addition to providing turnkey plants and galvanising equipment, we also provide customization based on the client's requirements. With our extensive experience in providing solutions and products, we provide premium-grade replacement parts that are tailored to your specific needs. Every replacement component guarantees the greatest assistance and outstanding.

After Sales Service

Appropriate after-sale support is essential to your galvanising plant's functionality and security. Our clients are our first concern at Polytech Projects LLP. Not only do we state this, but every member of our team maintains this viewpoint. Not only do we assist you during the purchasing process, but we also remain available to assist you with any post-purchase needs. Our after-sale staff ensures that clients are happy with their purchases. If there is ever a performance issue, you can easily contact our professionals, who will take care of the problem.

Training and Development

Polytech Projects LLP is a provider of turnkey hot dip galvanising plants with the necessary competence, experience, and quality in the field. We provide a training and development service that involves educating your workers on the application and functioning of hot dip galvanising so you can get the most out of the plant asset. We would answer any questions your employees may have about their specific responsibilities, plant safety precautions, and optimal operating procedures. To guarantee "best practise," we educate your workers by walking them through each stage of the hot dip galvanising process.

Post Comissioning Support

success in terms of the impact of our equipment on the performance and long-term growth of our clients.

Zinc Kettle Replacement

The kettle holds utmost significance in the process of galvanising. Polytech Projects LLP offers premium zinc kettles with long-lasting galvanising that are efficient. With our Pulse-Fired High Velocity Furnaces, Kettle by Polytech Projects LLP can withstand high output levels for up to ten years. We customise zinc kettle for maximum efficiency based on your product and plant area. Our kettles are welded with electroslag and put through radiographic and ultrasonic testing. By using refractory casting fibre to insulate the bottom of the kettle and keep it from coming into direct touch with the burner's flames, we may prolong the kettle's lifespan.