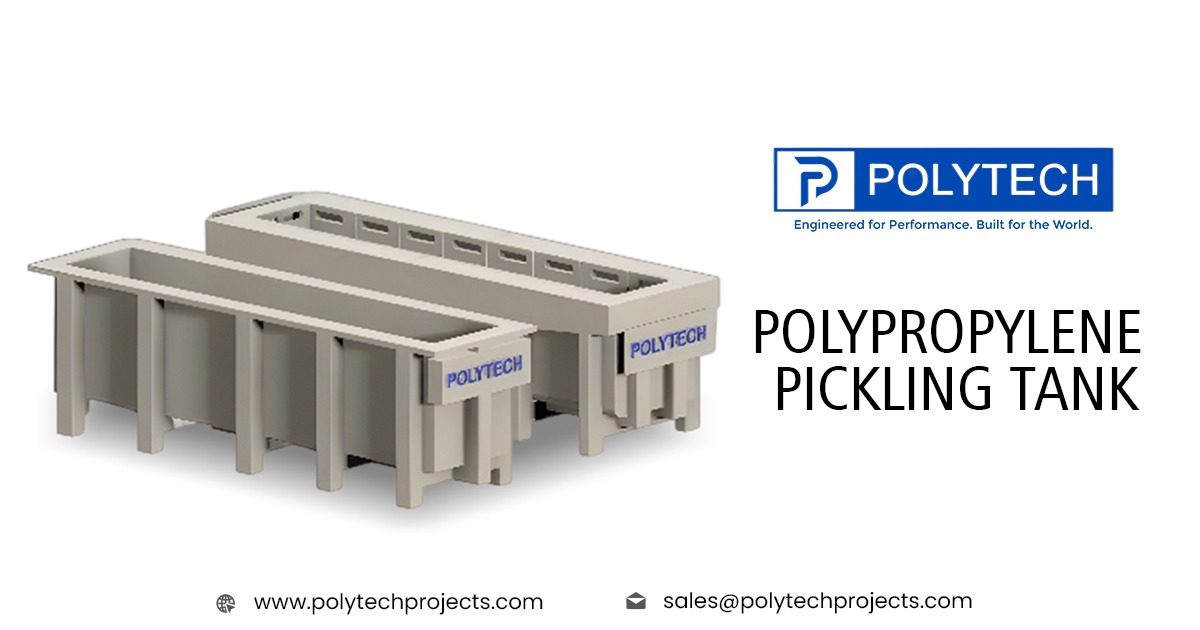

Polytech Projects LLP is a prominent Manufacturer, Supplier, and Exporter of Sulphuric Acid Picking Tank in Canada.

Our Manufacturing unit is based in Ahmedabad, Gujarat, India.

Our pickling tanks are designed using high-quality thermoplastics such as PP (Polypropylene), PVC, HDPE, and PVDF, ensuring excellent

performance in harsh acid environments.

Whether you are involved in metal surface treatment, galvanizing, or steel pickling operations, our tanks are built to meet the highest international

safety and quality standards.

Work of Sulphuric Acid Pickling Tank

A Sulphuric Acid Pickling Tank is primarily used in the metal finishing and steel processing industries to remove impurities, scales, and rust from metal

surfaces before further treatment or coating.

Functions of Sulphuric Acid Pickling Tank:

- Metal Cleaning: Removes oxides, rust, and mill scales from metal surfaces.

- Surface Preparation: Prepares the metal for processes like galvanizing, plating, or coating.

- Corrosion Prevention: Ensures a smooth and clean surface to enhance coating adhesion.

- Improved Finish: Provides a polished, uniform, and clean surface on steel products.

- Chemical Treatment Efficiency: Maintains chemical balance for effective pickling and minimal material loss.

Technical Specification:

- Type: Tanks

- Material: Common materials include plastic (polyethylene), steel, fiberglass, or concrete.

- Shape: Horizontal, Vertical

- Application: Industrial Liquids and Solids Storage, Storage of Agricultural Inputs

- Texture: Highly Soft

- Feature: Stability and Structural Integrity, Visibility of Liquid Level, Easy Access for Cleaning and Maintenance

- Moc: PP, HDPE, PVC, FRP, FRV

- Capacity: up to 1lac ltr

- Thickness: 3mm to upto 50mm

Features:

- High Chemical Resistance: Built to withstand concentrated sulphuric acid and other corrosive chemicals.

- Leak-Proof Construction: Seamless welding and stress-relieved joints ensure zero leakage.

- Durable Material: Made from PP, PVC, HDPE, or PVDF for long service life.

- Thermal Stability: Resistant to heat generated during acid reactions.

- Easy Maintenance: Smooth internal surface for easy cleaning and minimal residue buildup.

Applications Include:

- Steel & Metal Processing Units

- Galvanizing Plants

- Wire Drawing Industries

- Automotive Component Manufacturing

- Fabrication and Sheet Metal Workshops

- Chemical Processing Industries

- Electroplating and Surface Finishing Units

FAQs:

1. What material is best for a sulphuric acid pickling tank?

Polypropylene (PP) and PVC are ideal materials due to their strong acid resistance and durability.

2. Can these tanks be customized?

Yes, Polytech Projects LLP provides customized pickling tanks based on size, capacity, and application needs.

3. What safety measures are included in these tanks?

Our tanks include leak-proof joints, fume extraction systems, and reinforced structures to ensure operator safety.

4. Are these tanks suitable for outdoor installation?

Clients can install the tanks indoors or outdoors, and Polytech Projects LLP uses UV-stabilized material for outdoor installations.

Polytech Projects LLP is a prominent Manufacturer, Supplier, and Exporter of Sulphuric Acid Picking Tank in Canada and including locations in Toronto, Ottawa, Québec City, Vancouver, Montreal, Calgary, Edmonton, Winnipeg, St. John’s, Saint John, Victoria, Halifax Regional Municipality, Abbotsford, Hamilton, Fredericton, Windsor, Regina, Surrey, Saskatoon, Lethbridge, Thunder Bay, Kingston, Trois-Rivières, Sherbrooke, Greater Sudbury, Kitchener, Gatineau, Burnaby, Brampton, Barrie, Richmond, Moncton, London, Whitehorse, Mississauga, Saguenay, Prince George, Vaughan, Kamloops, North Bay, Mirabel, Oshawa, Kelowna, St. Catharines, Yellowknife, Niagara Falls, Brantford, Belleville, Airdrie, Guelph, Norfolk County.

For detailed information or inquiries, please feel free to contact us.

Call Us: +91 9408908275

Email Us: sales@polytechprojects.com

View Product: Click here