Polytech Projects LLP is a Manufacturer, Supplier, and Exporter of Pickling Tank in Mexico.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

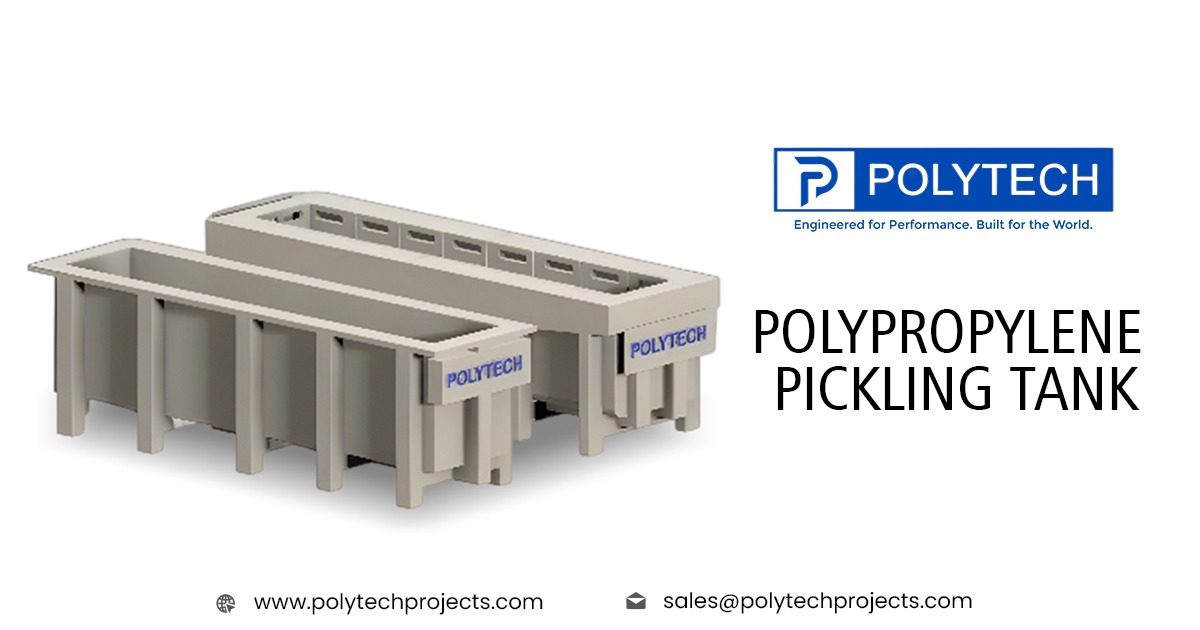

A pickling tank is a heavy-duty container that industrial workers use to clean metal surfaces with acid.

Used in steel processing, galvanizing, and tube manufacturing, it effectively prepares metals by removing surface contaminants completely.

The pickling process eliminates rust, grease, scale, and impurities before subsequent treatments like electroplating, painting, or galvanizing occur.

Manufacturers construct these tanks from chemical-resistant materials such as Polypropylene (PP), HDPE, or FRP for long-term durability.

Their corrosion resistance ensures safe, efficient, and extended use when handling aggressive acids in demanding industrial applications.

Features:

✅ High Chemical Resistance: Safe for long-term use with aggressive acids.

✅ Leakproof Construction: Butt-welded or extruded welding for complete sealing.

✅ Reinforced Structure: With FRP or steel for added load strength.

✅ Thermal Stability: Withstands high operating temperatures.

✅ Custom-Built Designs: Tailored to your application, dimensions, and layout.

✅ Fume Control System Ready: Optional integration with fume scrubbing systems.

✅ Corrosion-Free: 100% rust-proof structure for longer life and minimal maintenance.

Applications:

Steel and stainless steel surface treatment

Galvanizing plants (pre-cleaning)

Wire and cable industries

Pipe and tube manufacturing

Sheet metal fabrication

Heat exchanger and radiator manufacturing

Foundries and casting cleaning

Frequently Asked Questions (FAQs):

Q1: What acid is used in a pickling tank?

A1: Industry professionals most commonly use hydrochloric acid (HCl). They also use sulfuric acid (H₂SO₄), nitric acid, and hydrofluoric acid depending on the metal type and oxide layers.

Q2: Can the tanks be customized for our existing layout?

A2: Yes. Polytech Projects LLP specializes in customized tanks designed to fit your plant’s space, operations, and capacity requirements.

Q3: What maintenance is required?

A3: Minimal. Periodic cleaning and checking of welds and acid-resistant fittings. We provide maintenance guides and service support as well.

Polytech Projects LLP is a Polypropylene Tank in Mexico Including Mexico City, Guadalajara, Juárez, Tijuana, León, Nezahualcóyotl, Monterrey, Zapopan, Naucalpan, Chihuahua, Mérida, Guadalupe, San Luis Potosí.

For further details and inquiries, please feel free to contact us.